Composite Repair for Pipe suffering from External Damage

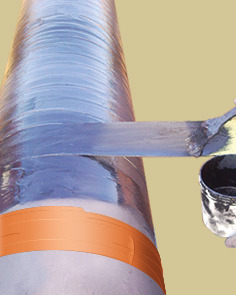

REINFORCEKiT® 4D-EC (R4D-EC) is a long-term composite repair system for pipes suffering from external corrosion and mechanical damage.

The original Brisma Africa concept is an association of Kevlar® tape and specific bi-component epoxy resin called R3X1060.

REINFORCEKiT® 4D is a wet lay-up system, wrapped helicoidally around the pipe in order to bring the mechanical resistance to the damaged pipe section.

Designed according to ISO 24.817 and ASME PCC-2 standards, this product will restore pipe original integrity. There is no limit in terms of pipe diameter and pressure, and it could be used without shutdown from -50°C up to +55°C | (-58°F to +131°F).

We have developed our own software R.E.A (Reinforcekit Engineering Analysis) to design the composite repair and define the material requirements in accordance with international standards.

USES

- Reinforce pipe suffering from:

- External corrosion

- Pitting

- Dent

- Weld defect

- Mechanical damage

APPLICATIONS

- Onshore and offshore (topside)

- All pipe geometries including welds, elbows and tees

- All pipe sizes (no limitation)

- High pressure pipeline

- Pipe operating from -50°C up to +55°C

- Pipe transporting most common fluid and gas

BENEFITS

- Online repair

- Non-conductive repair

- No hot work

- Long-term performance

REINFORCEKiT®4D-EC Main Technical Data

| Use: | PIPE REINFORCEMENT & COMPOSITE REPAIR FOR EXTERNAL CORROSION |

|---|---|

| Pipe diameter: | No limitation |

| Pipe temperature: | -50°C / +55°C (-58°F / +131°F) |

| Application temperature: | +10°C / +55°C (+50°F / +131°F) |

| Fiber: | Kevlar® |

| Resin: | R3X1060 |

REINFORCEKiT®4D-EC Implementation Steps