Online Leak Sealing

Emergency Pipeline Repair System (EPRS)

STOPKiT® is the most efficient repair in the world able to seal a leak online in few minutes.

It stops various types of leak (oil, gas, water …) on pipe diameters from 4’’ to 56’’ and is also applicable on specific geometries (oval pipe, elbow) and irregularities like welds.

This patented product is an emergency and temporary system and is available under several models (depending on pipe and hole diameter) and for various environments (onshore, offshore and subsea).

Pressure up to 80 bars can be stopped for hole diameter inferior to 10mm (patch size 50x100mm). In case of hole diameter up to 50mm, leaks can be sealed up to 30 bars (patch size 100x100mm). The installation can be done without shutting down the line pressure.

USES

- Emergency and temporary repair for leaking pipe

APPLICATIONS

- Onshore, Offshore and Subsea

- Suitable for weld, elbow, oval pipe ...

- Pipe diameters from 4" to 56"

- Pipe temperatures from -20°C to +80°C

(-4°F to +176°F) - Pipe transporting most common fluid and gas

BENEFITS

- No shutdown required

- No additional load on pipe (light product)

- Quick installation

- Easy to store

- Shelf life: 5 years

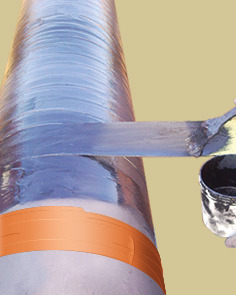

STOPKiT® Concept

The system operates by concentrating all the needed stress in the pipe at the defect location. The hoop stress needed to stop the leak is brought by the technical strap and the screws. The strong fibers of the strap are temperature and stress resistant.

ONSHORE ENVIRONMENT

STOPKiT® 50

Max. pressure 80 bars (1160 psi)

-20°C/+80°C

(-4°F/+176°F)

STOPKiT® 100

Max. pressure 30 bars (435 psi)

-20°C/+80°C

(-4°F/+176°F)

OFFSHORE / SUBSEA ENVIRONMENT

STOPKiT® 50

Max. pressure 80 bars (1160 psi)

+5°C/+80°C

(+41°F/+176°F)

STOPKiT® 100

Max. pressure 30 bars (435 psi)

+5°C/+80°C

(+41°F/+176°F)

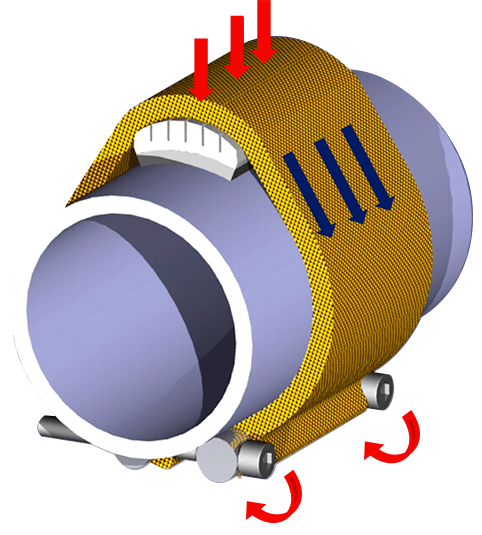

REINFORCEKiT®4D-IC Implementation Steps