Online Repair for SF6 Leaking Flange

REFLANGEKiT® is a SF6 leak sealing technique for flanges applicable online and under pressure.

REFLANGEKiT® has been designed, developed and tested in partnership with EDF R&D (French Electricity Supplier). Various pressure tests and aging tests have been performed internally and in EDF laboratories in order to propose high quality product.

USES

- Repair SF6 leaking flange

APPLICATIONS

- Nuclear and power plant installations

- Adaptable to various types of flange

- Temperatures from -20°C to +65°C

(-4°F to +149°F)

BENEFITS

- Online & under pressure installation

- Non invasive system (none risk of resin intrusion into the flange)

- Bold and screw protection

- Easy disassembly

- Cost effective installation (costly consignation avoided)

REFLANGEKiT® Concept

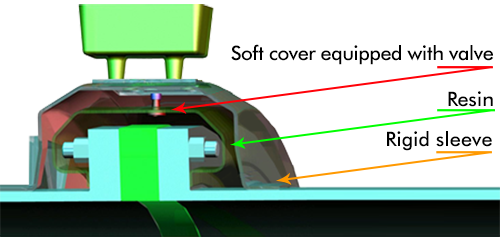

REFLANGEKiT® concept is based on a double shell system that encapsulates the leaking flange. The first shell made in PVC will cover and protect the flange and collect SF6 leaks. The second shell made in PET will contain 3X specific resin. An exhaust valve allows the gas getting out during resin injection. After overnight curing of resin, the valve is closed and sealed.

Thanks to this original system, flange and bolts are protected during resin injection and disassembly. The product can be easily removed without damage.

REFLANGEKiT® Implementation Steps