Pipe & Support Protection

Composite Repair for Corrosion Under Support (CUS)

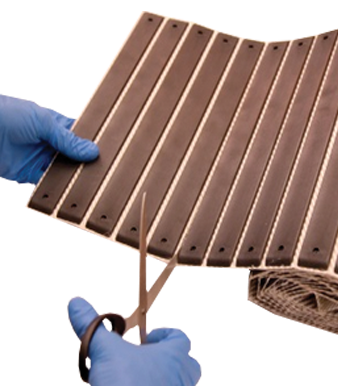

ROLLERKiT® is a preventive and curative repair system for corrosion under support, to be installed both on support or on pipe.

Depending on the level of corrosion, ROLLERKiT® can be applied directly on pipe for superficial corrosion.

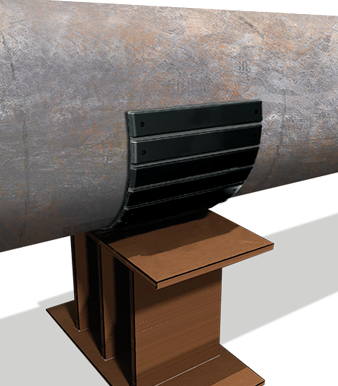

ROLLERKiT® on pipe

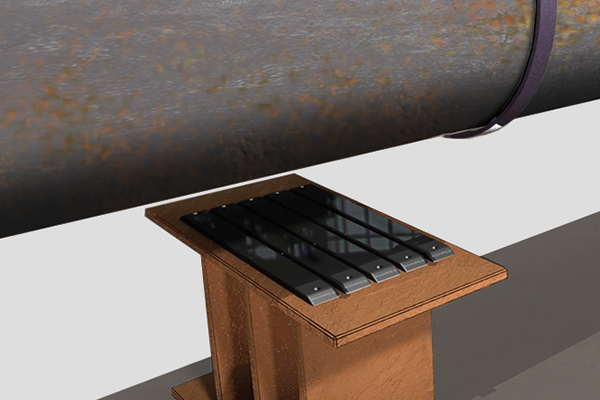

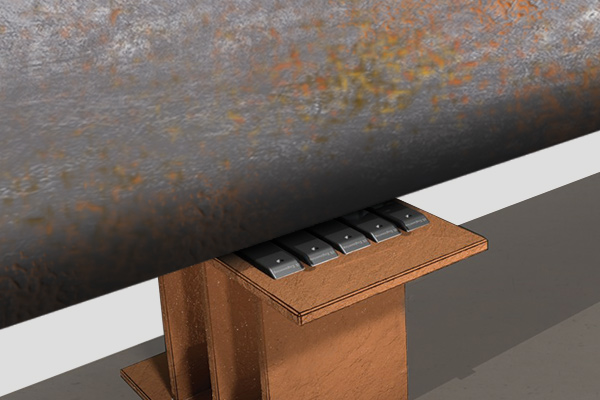

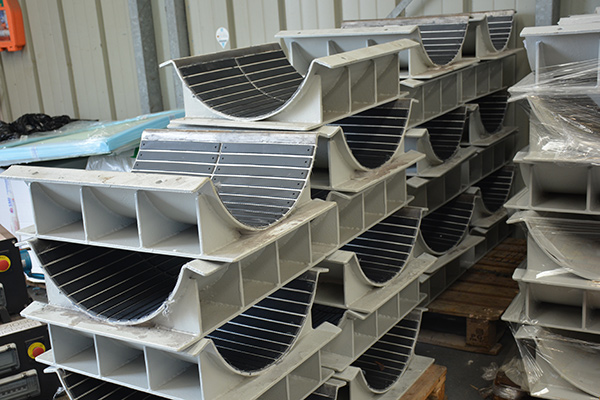

ROLLERKiT® on support

ROLLERKiT® on support

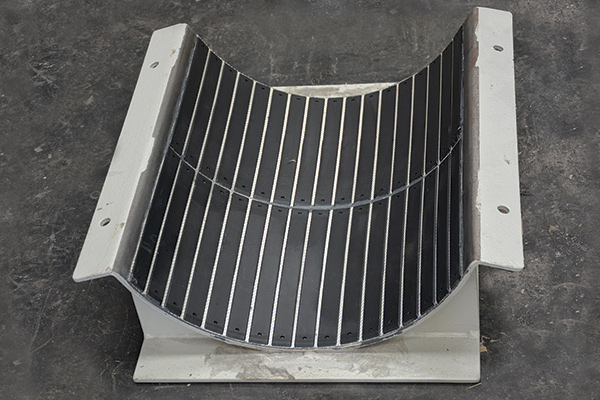

ROLLERKiT® is made of high polymer pads thermo-welded on glass fiber fabric and specific epoxy resin. Pads are designed to support the weight of the pipe according to ASME B31.1. Glass fiber fabric ensures the pads assembly, and applied with the resin on a corroded structure, it will stop the corrosion.

USES

- Protect the pipe at support area

- Prevent:

- Corrosion

- Abrasion

- Humidity

- Galvanic effects

- Friction

APPLICATIONS

- Onshore, Offshore and Subsea

- Old and new installations

- All pipe supports (steel, concrete ...)

- All design supports

- Pipe diameters from 4" to 56"

- Pipe temperature from -30°C to +150°C (-22°F to +302°F)

BENEFITS

- Long-term service lifetime

- Non-metallic solution

- Pipe integrity preserved

- Fast & easy installation

- Dual use: preventive & curative system

REINFORCEKiT®4D-ECHT Main Technical Data

| Use: | PIPE REINFORCEMENT & COMPOSITE REPAIR FOR EXTERNAL CORROSION |

|---|---|

| Pipe diameter: | No limitation |

| Pipe temperature: | -50°C / +110°C (-58°F / +230°F) |

| Application temperature: | +70°C / +110°C (+158°F / +230°F) |

| Fiber: | Kevlar® |

| Resin: | R3X1080 |

ROLLERKiT® Range

| Model | Pipe O.D. (inch) | Application | Temperatures | Resin | Length/Width/Thickness (mm) |

| ROL-28 | 4" to 28" | Onshore | -30°C/+150°C (-22°F/+302°F) | F3X8 | 3000 x 160 x 8 |

| ROL-56 | 30" to 56" | Onshore | -30°C/+150°C (-22°F/+302°F) | F3X8 | 3000 x 300 x 12 |

| ROS-28 | 4" to 28" | Offshore/Subsea | +50°C (+122°F) max. | P3X32 | 3000 x 160 x 8 |

| ROS-56 | 30" to 56" | Offshore/Subsea | +50°C (+122°F) max. | P3X32 | 3000 x 300 x 12 |

ROLLERKiT® Components

ROLLERKiT® Implementation Steps

on ROLLERKiT®

on the pipe