Composite Repair for Pipe suffering from External & Internal Damage (High Temperature - Up to +150°C)

REINFORCEKiT® 4D-HT+ (R4D-HT+) is a long-term composite repair system for pipes suffering from external/internal corrosion and through-wall defects at very high temperature (up to +150°C).

The original Brisma Africa concept is an association of Kevlar® tape and specific bi-component epoxy resin called R3XHT+.

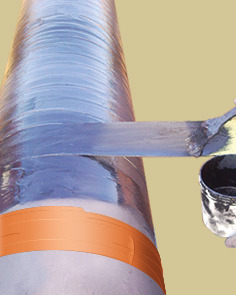

REINFORCEKiT® 4D is a wet lay-up system, wrapped helicoidally by external application around the pipe in order to bring the mechanical resistance to the damaged pipe section.

Designed according to ISO 24.817 and ASME PCC-2 standards, this product will restore pipe original integrity. There is no limit in terms of pipe diameter and pressure, and it could be used without shutdown (except in case of leakage) from -50°C up to +150°C (-58°F to +302°F). In case of leakage the process must be stopped prior to composite application.

We have developed our own software R.E.A (Reinforcekit Engineering Analysis) to design the composite repair and define the material requirements in accordance with international standards.

USES

- Reinforce pipe suffering from:

- Internal corrosion

- Through-wall defect

- Pinhole

- Crack

- Severe abrasion/erosion

- Leak

APPLICATIONS

- Onshore and offshore (topside)

- All pipe geometries including welds, elbows and tees

- All pipe sizes (no limitation)

- High pressure pipeline

- Pipe operating from -50°C up to +150°C

- Pipe transporting most common fluid and gas

BENEFITS

- Online repair

- Non-conductive repair

- No hot work

- Long-term performance

REINFORCEKiT®4D-HT+ Main Technical Data

| Use: | PIPE REINFORCEMENT & COMPOSITE REPAIR FOR EXTERNAL CORROSION |

|---|---|

| Pipe diameter: | No limitation |

| Pipe temperature: | -50°C / +150°C (-58°F / +302°F) |

| Application temperature: | +40°C / +90°C (+104°F / +194°F) |

| Fiber: | Kevlar® |

| Resin: | R3XHT+ |

REINFORCEKiT®4D-HT+ Implementation Steps