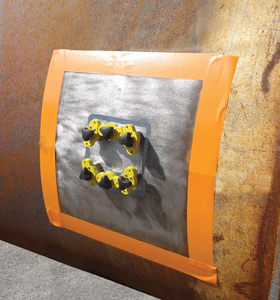

Emergency Repair System for Damaged Tank

TANKiT® is an emergency and temporary reinforcement solution for damaged tanks and pressured vessels suffering from corrosion defects (internal/external corrosion) up to 100mm hole size.

TANKiT® is a multi-layers product using a cold welded steel plate and Kevlar® patches impregnated with 3X specific resin. It can be applied without shutdown, unless active leakage.

This pre-engineered product is sold in ready-to-use kit and can be used only in specific cases (up to 100mm defect size and up to 20m diameter tank).

USES

- Repair external/internal corrosion

- Repair through-wall defects up to 100mm

- Stop the corrosion (if external defect)

APPLICATIONS

- Onshore and offshore installations

- Various tank designs and up to 20m tank diameter

- Temperature up to +60°C (+140°F)

- Compatible with most common fluid and gas

BENEFITS

- No engineering, no calculations

(ready-to-use) - Online repair (except for hole)

- No heating or post-curing required

- Cold welding system

- Cost effective solution

TANKiT® Main Technical Data

| Use: | TANK REINFORCEMENT – ONSHORE & OFFSHORE |

|---|---|

| Service temperature: | -50°C / +60°C (-58°F / +140°F) |

| Application temperature: | +10°C / +60°C (+50°F / +140°F) |

| Maximum tank diameter: | Up to 20m |

| Maximum hole size: | Up to 100mm |

| Maximum pressure: | Depends on tank and defect diameter - See charts below (TANKiT® capacities) |

TANKiT®Implementation Steps

Surface preparation SA 2½ / St3

Steel plate application (with filler & magnets)

Kevlar® patch with 3X resin application (5 layers)

TANKiT® installed & traceability