High–efficient milling system in functional and compact design up to 55 kW.

Options: ATEX zone 0/1/2, Vacuum, PLC‒control, Ceramic version

TORUSMILL® SK115

TORUSMILL® SK115

TORUSMILL® SK122

TORUSMILL® SK537

TORUSMILL® SK1055

| TORUSMILL® type |

Power kW |

Standard product volume litre |

Container capacity litre |

|---|---|---|---|

| Basket mill TORUSMILL® SK115 | 15 | 35 ‒ 400 | 75 ‒ 500 |

| Basket mill TORUSMILL® SK122 | 22 | 35 ‒ 400 | 75 ‒ 500 |

| Basket mill TORUSMILL® SK537 | 37 | 100 ‒ 1000 | 200 ‒ 1250 |

| Basket mill TORUSMILL® SK1000 | 45 / 55 | 250 ‒ 1600 | 500 ‒ 2000 |

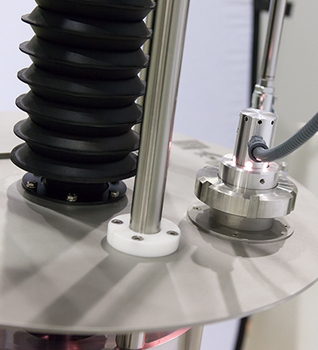

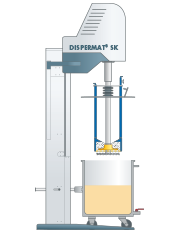

The TORUSMILL® SK are high-efficient basket mills with which excellent grinding results can be achieved in very short time. The TORUSMILL® SK is available in versions from 15 kW upto 55 kW drive power for processing low and medium viscous products. The TORUSMILL® clamping device is suitable for container volumes upto 2000 l. The rapid circulation of the mill base through the grinding basket is achieved through an integrated, patented pump wheel. This provides a high number of passes, and a narrow particle size. The dissolver disc mounted below the milling basket ensures a milling of the millbase within the milling container with minimal dead volumes.

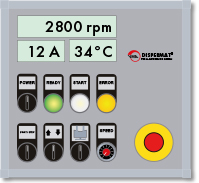

The TORUSMILL® SK can also be fitted with the PLC-control. The graphic display allows for an indication of the operational parameters such as speed, power output, peripheral speed of the milling tool, torque and product temperature. The combination of a graphic display and the standardized PLC-control allows for an extension as well as for an adaptation of the control system to further process control applications at any time.

The container with the liquid component is moved into position under the TORUSMILL® SK. The dissolver disc is lowered down into the liquid.

The TORUSMILL® SK now starts the actual dispersion process for extremely fine grinding. When the dissolver disc and the milling system are located above the product surface, product residue in the grinding basket is centrifuged out by briefly running the milling and dissolver discs.

The milling system is now completely raised and the container with the ground finished product is removed. Cleaning the milling system is carried out in a separate conical container in order to minimise the required amount of cleaning fluid.