Fine grinding also for temperature sensitive products. Options: Milling system (milling chamber and milling rotor) made of ceramic, PLC control, ATEX zone 0/1/2

DISPERMAT® RS10 (ATEX)

DISPERMAT® RS10 (ATEX)

DISPERMAT® RS10 (ATEX)

DISPERMAT® RS10 (ATEX)

DISPERMAT® RS10 (ATEX)

DISPERMAT® RS5 and DISPERMAT® RS10

C ‒ technology

M-EX ‒ technology (ATEX)

| DISPERMAT® type |

Power kW |

Product volume litre/hour |

Milling chamber litre |

Speed rpm |

|---|---|---|---|---|

| Bead mill DISPERMAT® RS5 | 15 | 25 ‒ 250 | 5 | 0 ‒ 2600 |

| Bead mill DISPERMAT® RS10 | 37 | 50 ‒ 450 | 10 | 0 ‒ 2100 |

Bead mill DISPERMAT® RS for fine grinding for the pass and for circulation process

The DISPERMAT® RS is a horizontal operating bead mill. The compact, functional design ensures a very easy and safe handling and rapid assembly and disassembly of milling chamber and milling rotor. The bead mill RS can be operated in the pass as well as in the circulation process and guarantees for outstanding grinding results. Since the heat generated during the milling process is dissipated through a highly efficient cooling circuit in the rotor, heat–sensitive products can also be very easily finely ground.

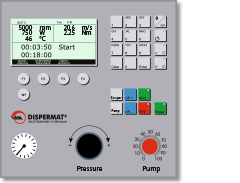

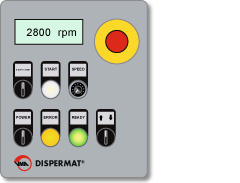

For every challenge the suitable process control. The DISPERMAT® RS can be equipped with different control systems. For example:

The graphic display allows for an indication of the operational parameters such as speed, power output, peripheral speed of the milling tool, torque and product temperature. The combination of a graphic display and the standardized PLC-control allows for an extension as well as for an adaptation of the control system to further process control applications at any time.