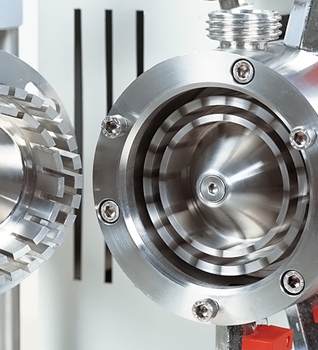

Rotor-Stator dispersion system for dispersing under pressure or vacuum.

Optional: explosion proofness according to ATEX.

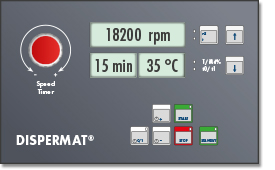

DISPERMAT® AS

Indications in the display: speed, timer, torque, product temperature, power input and peripheral speed of the dispersion tool

| DISPERMAT® type |

Power kW |

Peripheral speed of the rotor meter/second |

Speed rpm |

Flow rate H2O litre/min |

| Homogenizer DISPERMAT® AS |

1.1 | 25 | 0 ‒ 6000 | 10.6 |

Homogenizer for one-pass- or circulation procedure with easily changeable rotor- stator system

The DISPERMAT® AS homogenizer is a rotor-stator dispersion system. The DISPERMAT® AS rotor and stator consists of coaxially intertwined rings designed with narrow radial slots. The rotor runs at high speed across the stator. The substance to be dispersed is fed into the centre of the rotor-stator system and centrifugally accelerated by the motion of the rotor. As it passes through the rotor-stator dispersion head, the substance is dramatically accelerated both tangentially and radially. The high frequency shearing force and turbulent flow conditions ensure optimum dispersion and emulsifying action producing very fine droplets with a large effective surface area (e.g. oil/water or water/oil emulsions).

The dispersion system has a mechanical seal with an integrated pressure system. The DISPERMAT® AS homogenizer can be operated both in the passthrough as well as the circulation method. All parts that are in contact with the product are made of stainless steel. Depending on the application there are various Rotor-Stator systems available. With the homogenizer DISPERMAT® AS, the operating parameters dispersion power, speed, torque and product temperature are constantly being measured and displayed on the screen. In this way, the “constant RPM“ operating mode provides a permanent overview of parameter changes during the dispersion process.