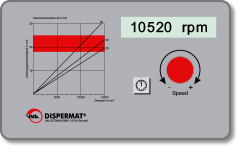

Indications in the display: speed, timer, torque, product temperature, power input and peripheral speed of the dispersion tool

| DISPERMAT® type |

Power kW |

Speed rpm |

Shearing actions per minute |

Product volume litre |

|---|---|---|---|---|

| DISPERMAT® CC | 0.15 | 0 ‒ 16000 | 64000 | 0.1 ‒ 0.5 |

Coil‒Coatings testing device for up to 64000 shears per minute

During the coating of steel or aluminium strips in high speed coil coating machines the liquid coatings (varnishes) are stressed to an extremely high degree. Therefore it is absolutely essential to test the mechanical hardness of these varnishes in the laboratory first. During the test the coating is poured into a small container and subjected to very high shear conditions (up to 64000 rpm). These conditions are created by the contrarotating high speed propellers.

After the test the coating is applied to a test panel and baked at different temperatures. The subsequent testing of the surface shows whether the coating meets the required quality standards.

The dispersion system has a mechanical seal with an integrated pressure system. The DISPERMAT® AS homogenizer can be operated both in the passthrough as well as the circulation method. All parts that are in contact with the product are made of stainless steel. Depending on the application there are various Rotor-Stator systems available. With the homogenizer DISPERMAT® AS, the operating parameters dispersion power, speed, torque and product temperature are constantly being measured and displayed on the screen. In this way, the “constant RPM“ operating mode provides a permanent overview of parameter changes during the dispersion process.