starting from now the modular vacuum dispersion system CDS is available with scraper for high viscous media.

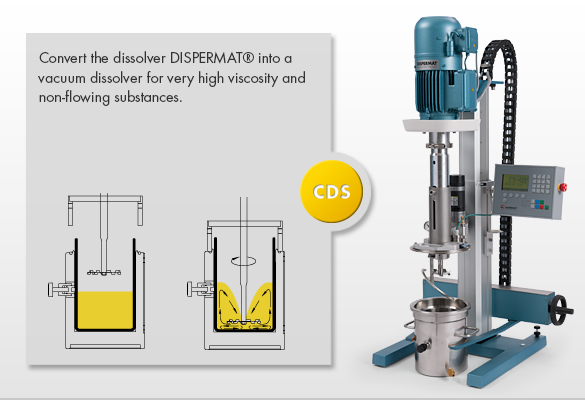

The CDS dispersion system enables the dispersion process to be carried out in single walled containers, in a closed system under vacuum.

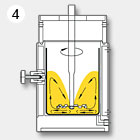

The dispersion process can be continuously monitored through the glass cover. With the correct operation the grinding stock is put into a rolling, turbulence free movement (Doughnut-effect).

DISPERMAT® CV3-PLUS with modular vacuum system CDS

DISPERMAT® CA40 with modular vacuum system CDS. Type: double walled container receptacle with glass cover.

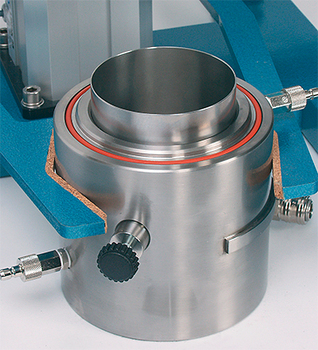

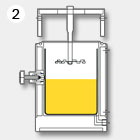

The picture shows the double walled version of the container receptacle made of stainless steel (temperature controlled) of the modular vacuum system CDS.

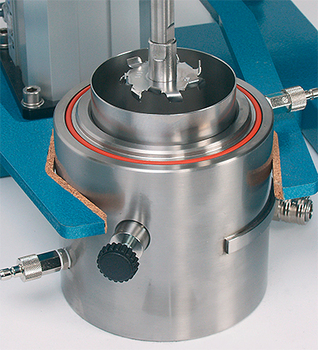

The single walled containers are placed into the container holder and secured in place.

The liquid and powder components are added and the glass cover lowered into place.

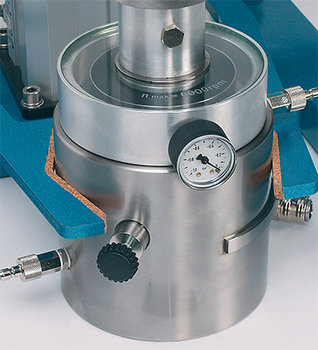

The actual dispersion process can then be carried out under vacuum. The dispersion process can be continuously monitored through the glass cover.

| CDS system type |

Product volume, litre |

Container capacity, litre |

Recommended DISPERMAT® Dissolver type |

| A single or double walled container receptacle with glass cover is available | |||

| Vacuum dispersion system CDS 250 | 0.2 | 0.25 | LC30 – LC220-6 │ CV-PLUS │ CN10 – CN40 CA │ AE01 – AE06 │ LC-EX AE01-EX – AE06-EX │ R30 │ R11 – R14 |

| Vacuum dispersion system CDS 500 | 0.4 | 0.5 | LC30 – LC220-6 │ CV-PLUS │ CN10 – CN40 CA │ AE01 – AE06 │ LC-EX AE01-EX – AE06-EX │ R30 │ R11 ‒ R14 |

| Vacuum dispersion system CDS 1000 | 0.8 | 1 | LC30 – LC220-6 │ CV-PLUS │ CN10 – CN40 CA │ AE01 – AE06 │ LC-EX AE01-EX – AE06-EX │ R30 │ R11 ‒ R14 |

| Vacuum dispersion system CDS 2000 | 1.6 | 2 | LC110-06 – LC220-6 │ CV4-PLUS │ CN10 – CN40 CA │ AE01 – AE06 │ LC75-EX AE01-EX – AE06-EX │ R11 ‒ R14 |

| Vacuum dispersion system CDS 3000 | 2.4 | 3 | LC110-12 – LC220-6 │ CV4-PLUS │ CN10 – CN80 CA │ AE01 – AE10 │ AE01-EX – AE10-EX R11 ‒ R14 |

| Vacuum dispersion system CDS 5000 | 4 | 5 | LC110-12 – LC220-6 │ CN │ CA AE │ AE-EX │ R11 ‒ R14 |

| A single or double walled container with an aluminium cover is available (without container receptacle) | |||

| Vacuum dispersion system CDS 10000 | 8 | 10 | LC110-12 – LC220-6 │ CN │ CA40 – CA60 AE │ AE-EX |

| Vacuum dispersion system CDS 20000 | 16 | 20 | LC110-12 – LC220-6 │ CN │ CA60 AE03 – AE12 │ AE03-EX – AE12-EX |

| Vacuum dispersion system CDS 25000 | 20 | 25 | LC220-6 │ CN40 – CN100 AE06 – AE12 │ AE06-EX – AE12-EX |

The CDS dispersion system enables the dispersion process to be carried out in single walled containers in a closed system under vacuum. The single walled containers are placed into the container receptacle and secured in place. If the dispersion process needs to be cooled a double walled container receptacle is available. After the liquid and powder components have been added, the glass cover can be lowered onto the container receptacle over the vacuum shaft guide tube. The actual dispersion process can now be run and the product is set into a turbulence free rolling motion. If vacuum is required the vacuum pump can be switched on. The impeller height can be easily be raised or lowered during the dispersion process even under vacuum. The dispersion process can be observed clearly through the large glass cover. All CDS systems are available single or double walled (temperature controlled).

The following picture shows the dispersion process with the vacuum system CDS 500 with double walled container receptacle:

|

|

|

| |||

| The picture shows the double walled version of the container receptacle made of stainless steel (temperature controlled) of the modular vacuum system CDS. | The single walled container is fixed in the double walled container receptacle and the powdery component is stirred into the liquid component. | After mixing the liquid and the powdery component the glass cover is placed upon and the dispersion process starts under vacuum. | With the correct operation the grinding stock is put into a rolling, turbulence free movement (Doughnut-effect). The results achieved with the laboratory dissolver DISPERMAT® can be excellently transferred to working conditions. |

This completely new designed innovative vacuum system CDS allows for the first time for the dispersion of high viscous products by using an integrated scraper system. The CDS system which is available for many DISPERMAT® dissolvers is fitted with a ultra-bright LED interior lighting as well as with an infrared temperature measurement.