Nano bead mill for milling beads of 0.1 mm.

Optional: explosion proofness according to ATEX.

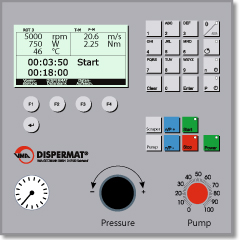

Bead mill SL 12 with C-control. Accessories: Supply vessel made of stainless steel

DISPERMAT® SL-C in stainless steel

DISPERMAT®

type |

Power

kW |

Speed

rpm |

Milling chamber

litre |

Product volume

litre |

| Nano bead mill DISPERMAT® SL5-NANO |

1.1 |

0 - 6000 |

0.05 |

0.05 - 0.75 |

| Nano bead mill DISPERMAT® SL12-NANO |

1.1 |

0 - 6000 |

0.125 |

0.15 - 0.75 |

| Nano bead mill DISPERMAT® SL25-NANO |

2.2 |

0 - 6000 |

0.25 |

0.3 - 2.5 |

| Nano bead mill DISPERMAT® SL50-NANO |

3 |

0 - 6000 |

0.5 |

0.5 - 10 |

| Nano bead mill DISPERMAT® SL100-NANO |

3 |

0 - 3000 |

1 |

1 - 20 |

| Nano bead mill DISPERMAT® SL200-NANO |

4 |

0 - 3000 |

2 |

2 - 50 |

Nano bead mill for repeatable dispersions with high power input

The nano bead mill DISPERMAT® SL-nano is a closed, horizontally operating nano bead mill with a high power input and extremely low clearance volume for circulation and pass procedure. The nano bead mill can be used for wet grinding in laboratory, techniques and the production.

Distinguishing marks of the nano bead mill:

- High grinding stock production due to pneumatic press out system

- Extremely small milling beads from 0.1 – 0.3 mm

- C-control with extensive process control

- Data interface for documentation and analysis

- Excellently suitable for research, development and quality assurance

- Compact design and very easy to clean

- High repeatability of the dispersions

- Scale up: easy transmission from laboratory results to production scale

- Modular design: a modification to larger beads is possible at any time

The milling system is made of wear resisting, high-alloyed special steel. As an option it is available in:

- Zirconoxyde ( ZrO2): no metallic abrasion

- Siliciumcarbide (SiSiC): very good caloric conductibility, no metallic abrasion

- Hard metal: good caloric conductibility, suitable for highly abrasive products

For every task the suitable technology.

Available control technologies for the bead mill DISPERMAT® SL

C and C-EX ‒ technology

- Data recording

recording of the process parameters with graphical indication

- Switch‒off parameters

Switch‒off function for temperature, speed, torque and power

- Database

100 individual PRESET configurations for speed, timer, switch‒off parameters etc.

- Power compensation

calibration of the net power

- WINDISP 7©

Data interface to WINDISP 7© software for documentation, analyses, research and development and quality control

- Graphic display

indications of speed, torque, power, product temperature, timer and peripheral speed

- Repeatability

dispersion method: constant speed and

constant power input for for an optimum

repeatability