| Dissolver DISPERMAT® LC-EX |

Dissolver DISPERMAT® AE-EX | |

| Product volume litre |

0.25 ‒ 5 | 0.25 ‒ 120 |

| Speed rpm |

0 ‒ 12000 | 0 ‒ 10000 |

| Power kW |

0.25 ‒ 0.75 | 0.55 ‒ 7.5 |

| Control panel | LC | M-EX and C-EX |

| Timer | no | yes |

| Height adjustment | electrical | electrical |

| Explosion protection | ATEX zone 2 | ATEX zone 0 / 1 / 2 |

Flexible. Powerful. Innovative. In combination with the modular dispersing and fine grinding systems the dissolver DISPERMAT® changes into a bead mill, a basket mill, a vacuum dissolver, a homogenizer and a dissolver for high viscosity products. The modular systems are easily adapted to the corresponding dissolver via the dissolver shaft or the adapter flange.

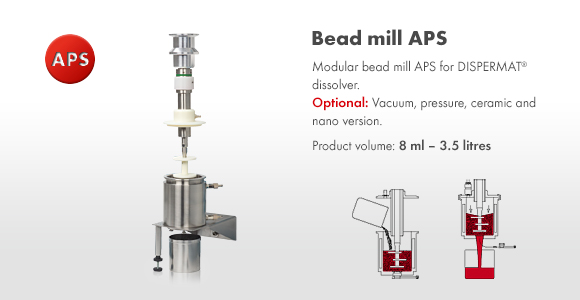

In combination with a DISPERMAT® dissolver the modular milling system APS is working as a closed batch bead mill.

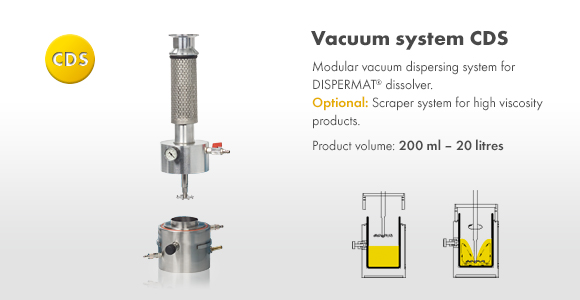

The modular vacuum dispersion system enables the dispersion process to be carried out in single or double walled containers under vacuum.

The modular and bearing free SR rotor-stator system is a dispersion system for batch processing low viscosity products.

In order to guarantee a perfect dispersion even with very high viscosity and non-flowing substances, very often a scraper system is absolutely essential.