2 in 1: patented basket mill with integrated dissolver in a new trend‒setting design from 15 to 55 kW. Options: ATEX zone 0/1/2, vacuum, PLC‒control, ceramic version

TORUSMILL® TM537

TORUSMILL® TM537

TORUSMILL® TM537

TORUSMILL® TM122

TORUSMILL® TM1000

| TORUSMILL® type |

Power kW |

Standard product volume litre |

Container capacity litre |

|---|---|---|---|

| Basket mill TORUSMILL® TM100 | 15 / 22 | 35 ‒ 200 | 75 ‒ 500 |

| Basket mill TORUSMILL® TM537 | 37 | 100 ‒ 1000 | 200 ‒ 1250 |

| Basket mill TORUSMILL® TM1000 | 45 / 55 | 250 ‒ 1600 | 500 ‒ 2000 |

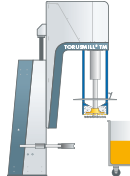

Trend of technology TORUSMILL® TM.

Highly efficient combination of dissolver and basket mill.

The TORUSMILL® TM is a patented dispersion system which allows for a

particularly economic and environmental dispersion of high quality

products. With the TORUSMILL® a predispersion with a dissolver disc and

afterwards the extremely fine grinding with an integrated basket mill

can be made in one process and one container. This innovation

intelligently combines proven high speed dispersion technology with a

basket mill system.

In operation, the TORUSMILL® is first used

to predisperse the product with a dissolver disc. During predispersion

the torus shaped basket is "parked" in the upper part of the machine.

After predispersion the milling basket containing the milling beads and

the milling tool is lowered into the mill base and the fine milling

process can begin. The fast circulation of the millbase within the

milling basket is generated by the dissolver disc and integrated pump

wheel; because of this excellent dispersion results and a very narrow

particle size distribution can be achieved very quickly. Due to the fact

that no pumps, pipes, valves and additional containers are necessary,

the cleaning is very easy and a quick change of the millbase is

possible.

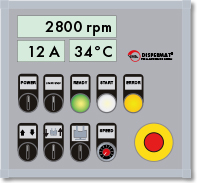

The TORUSMILL® TM can also be fitted with the PLC-control. The graphic display allows for an indication of the operational parameters such as speed, power output, peripheral speed of the milling tool, torque and product temperature. The combination of a graphic display and the standardized PLC-control allows for an extension as well as for an adaptation of the control system to further process control applications at any time.

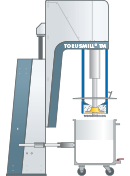

The container with the liquid component is moved into position under the TORUSMILL® TM and the dissolver disc is lowered down into the liquid.

For now the milling basket is “parked” underneath the container cover.

The powdered component is fed into the liquid phase at low speed, wetted and premixed.

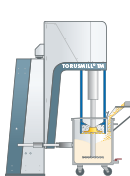

The premixed product is dispersed with the dissolver disc in the classical manner.

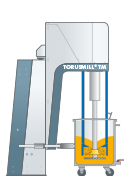

After dispersion the milling basket is lowered into the pre dispersed mill base within the closed container. The TORUSMILL® TM now starts the actual dispersion process for extremely fine grinding. The patented dispersion system reaches excellent dispersion results and a narrow particle size distribution in a very short time.

The fine grinding process is now successfully finished.

Cleaning the milling system is carried out in a separate conical container in order to minimise the required amount of cleaning fluid.