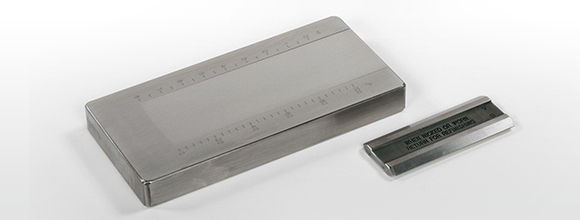

The grind gage is used for the determination of the fineness of grain and large particles or agglomerates in a dispersion

In addition to our extensive range of stirring, dispersing and milling accessories, we produce varying designs on request.

Our experienced engineers are glad to advise you accordingly.

| Grind gage | Pulling-off surface | Range |

| Grind gage 25 | 50 x 130 mm | 0 - 25 µ (Micro) |

| Grind gage 50 | 50 x 130 mm | 0 - 50 µ (Micro) |

| Grind gage 100 | 50 x 130 mm | 0 - 100 µ (Micro) |

During the dispersion process solids of a coating material are

pulverized into smaller particles. The dispersion grade has an effect on

the physical and optical characteristics of the coating. The grind gage

is used for the determination of the fineness of grain and large

particles or agglomerates in a dispersion. It does not define the real

grain size or grain distribution. Grind gages are used for quality

inspection in a production, storage and application of dispersions in

the varnish, pigment, printing ink, paper, ceramic, pharma, food and

many other industries.

The grind gage is a flat steel standard

with one or two flat, wedge-shaped grooves in the surface. These grooves

run from a maximum depth on one end of the grind gage consistendly up

to the zero point on the other end of the steel standard.

0 Hegmann = 100 µm grain size

4 Hegmann = 50 µm grain size

8 Hegmann = 0 µm grain size

The

first test of the fineness of grain is generally made by using a grind

gage. During the dispersion process a sample is taken and stripped with

the blade. The exact fineness of grain is fixed depending on the product

by different methods.